ISEF 2025: CFD Winglet Analysis

ISEF ‘24 Finalist. Thomas Edison Science & Engineering Fair 2nd Best in Fair. 2024.

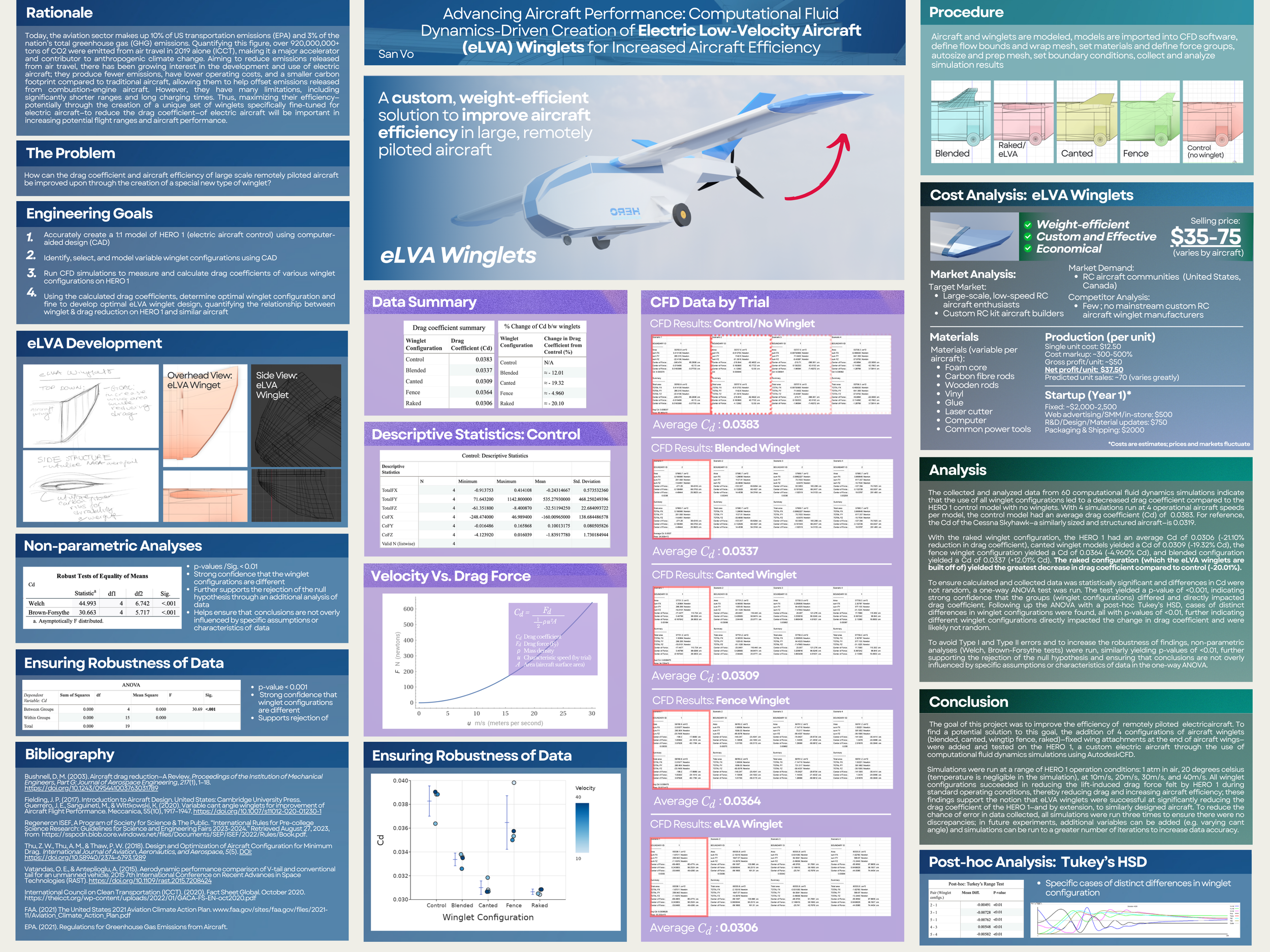

I conducted an independent aerospace research project developing electric low-velocity aircraft (eLVA) winglets using computational fluid dynamics (CFD) to improve aerodynamic efficiency in large, remotely piloted electric aircraft.

The project aimed to reduce drag coefficients and extend flight endurance — a critical challenge for long-range electric platforms. This work qualified for the International Science and Engineering Fair (ISEF), one of the world’s top STEM research competitions. This project directly reinforces my broader goal as an engineer: building systems that combine technical rigor with practical, real-world impact. Improving aerodynamic efficiency isn’t just about equations — it’s about designing aircraft that fly longer, safer, and more sustainably. The experience taught me how to integrate simulation, data analysis, and manufacturability into a cohesive engineering pipeline. Whether I’m working on robotics, aviation, or digital systems, that same mindset guides me: engineer solutions that are deeply technical and human centered.

Objectives

Model the HERO electric aircraft in CAD and run iterative CFD simulations to quantify how different winglet geometries affect drag.

Identify the most efficient low-velocity winglet configuration for slow-speed, large-span RPAS.

Validate results statistically using non-parametric tests, ANOVA, and Tukey’s HSD to ensure robustness across trials.

Produce a design optimized for manufacturability, weight efficiency, and cost.

Contributions & Outcomes

Created full CAD models of the baseline wing and multiple winglet variants (blended, canted, fenced, eLVA).

Ran over 60 CFD simulations with consistent meshing, boundary conditions, and velocity profiles.

Performed full statistical analysis of drag coefficients across trials (mean, SD, non-parametric tests, ANOVA).

Conducted materials and cost analysis, designing the winglet for low-cost, scalable production.

Synthesized all findings into a comprehensive technical poster presented at ISEF.

The custom eLVA winglet achieved the lowest drag coefficient (~0.0306), outperforming all control and comparison geometries.

Statistical tests confirmed meaningful, repeatable improvements: canted and eLVA winglets showed significant reductions in drag relative to the baseline.

Demonstrated that low-velocity aircraft benefit from specialized winglet designs rather than scaling commercial aviation winglets downward.

Developed a manufacturable, weight-efficient solution with an estimated per-unit cost of $35–75, supporting real deployment in RC or mid-scale RPAS applications.

Technical Skills

Computational Fluid Dynamics: Airfoil meshing, flow domain setup, turbulence modeling, velocity sweeps, and parametric trials.

Aerospace CAD + Simulation: Solid modeling, control surface geometry, and aerodynamic surface optimization.

Data science & statistics: Non-parametric testing, ANOVA, Tukey’s HSD, ensuring statistical robustness.

Engineering economics: Cost modeling, materials sourcing, and production feasibility.

Research communication: Distilling complex CFD analysis into clear visuals, reports, and a competition-ready technical poster.

Me pointing at my name on the ISEF wall. May 2024.

Me and fellow delegates from southwest Florida at the ISEF venue. Los Angeles, May 2024.